OPTIMIZE LOAD EFFICIENCY AND MINIMIZE MATERIAL RETENTION.

Ground Force Dump Bodies are engineered and manufactured to increase your mine production and bottom-line profitability. These bodies are strategically designed the “right weight” and configuration for your specific mining application to ensure peak performance.

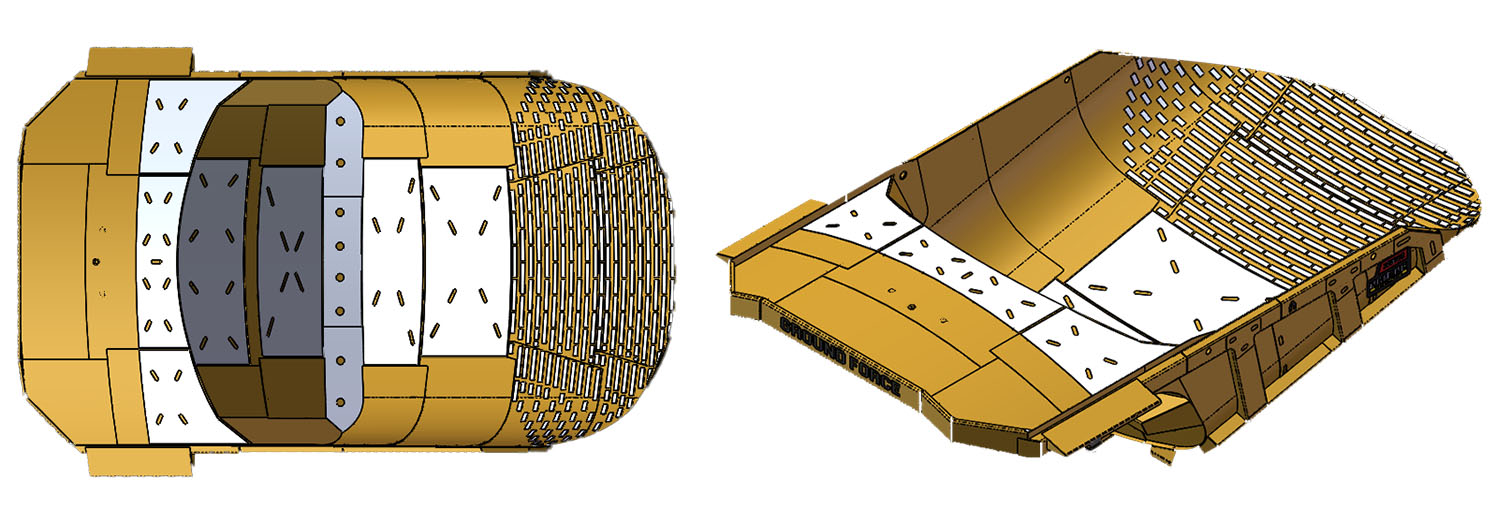

These bodies utilize an overlap shell design (patent pending), which lessens the amount of external structural support required without compromising strength. The overlap design steps open towards the rear of the body allowing for quicker material discharge and reduced carry-back by elimination of leading edges.

Our engineering team utilizes finite element analysis to ensure strength, durability, and longevity of these bodies. This ensures life expectancy for the most challenging applications and extreme conditions.

DUMP BODIES

CAPACITIES

40 – 400 ton (36 – 363 metric ton)

Discover the Benefits

INCREASED PAYLOAD:

Lightweight designs provide increased production and bottom-line profitability, our strategic engineering is proven and allows for peak performance.

REDUCED CARRY BACK:

Engineered with an overlap shell design, lessening the amount of external structural support without compromising strength. The overlap design allows for quick release of material reducing carryback.

MULTIPLE APPLICATIONS AND CONFIGURATIONS:

Purposely designed and manufactured for multiple applications, these bodies ship complete or in up to 4 pieces to reduce shipping costs.

SETTING THE STANDARD: PREMIUM SPECIFICATIONS IN EVERY BUILD.

Explore a range of special features, many of which are included as standard with our equipment. Capacities vary based on chassis size and weight distribution.

EXPLORE OUR STANDARD SPECIFICATIONS:

CUTTING-EDGE FEATURES & BENEFITS:

DISCOVER THE DIVERSITY IN OUR DUMP BODY MODELS

| CLASS | MODEL |

|---|---|

| *Ground Force Dump Bodies are PURPOSE DESIGNED & BUILT, offering bodies for multiple applications. | Body types available: Coal Bodies, Coal Combo Bodies, Overburden Bodies, Ore Bodies, Heated Bodies |

| 40 T (36 mt) | 40RWB |

| 60 T (55 mt) | 60RWB |

| 70 T (63.5 mt) | 70RWB |

| 100 T (90 mt) | 100RWB |

| 150 T (134 mt) | 150RWB |

| 200 T (177 mt) | 200RWB |

| 250 T (227 mt) | 250RWB |

| 320 T (290 mt) | 320RWB |

| 400 T (362 mt) | 400RWB |

*Capacities will vary depending on chassis size, weight distribution, and material density. All Ground Force Worldwide RWB Dump Bodies offer a variety of configurations and liner packages with the benefits of being ultra-lightweight in design. Designs for all chassis on the market today.

CUSTOM LINER PACKAGES TO EXTEND THE LIFE OF THE BODY

OUR ENGINEERING TEAM PROVIDES ONSITE ANALYSIS FOR YOUR WEAR PATTERNS.

Custom Liner packages are available with all our bodies. Our engineering department will work with you to ensure we have the most optimal liners in your body for your application. We study your wear patterns and design a liner program to suit those needs.

Ground Force Worldwide can provide you with many common options as well, such as rock ejector brackets, tailgates, safety latches, grease lines, light boxes, and fleet numbers.

LINER PACKAGES:

FOR RESOURCES AND SUPPORT, CONNECT WITH US TODAY

BROCHURE: Explore detailed information about our products.

PRODUCT CATALOG: Browse through our comprehensive product catalog.

MAINTENANCE VIDEOS: Access helpful videos for maintenance guidance.

INVENTORY: Stay informed about our current product availability.

For personalized assistance or further inquiries, please don’t hesitate to reach out to us directly. We’re here to help and ensure you have the information you need.

EXPLORE OUR RANGE OF OTHER COMPREHENSIVE SOLUTIONS