Ground Force Engineering Department: Driven by Customer Vision

Each mine is unique, with ever-evolving conditions and requirements. We acknowledge these nuances and approach each engineering endeavor with the tailored consideration it demands. Our team of dedicated and creative engineers designs each Ground Force product with the specific demands of its destined location. By incorporating feedback from our clients, we are in a constant state of refinement and enhancement of our designs to meet the industry’s shifting needs. Leveraging our unparalleled expertise, we address challenges with inventive resolutions.

Strong Knowledge of Mining Equipment and Application

Our engineering team has in-depth expertise in mining operations, equipment, and technology. This critical knowledge allows our team to optimize processes and make informed decisions to ensure we are providing the best engineering solution for the customers’ specific needs while holding to the high standards for quality, safe mining equipment.

We use Finite Element Analysis (FEA) to analyze and solve complex engineering problems. FEA allows our engineers to evaluate design alternatives virtually, accelerating the design process, and saving time and resources while optimizing designs, enhancing performance, efficiency, and safety.

Excellent Analytical and Problem-Solving Skills

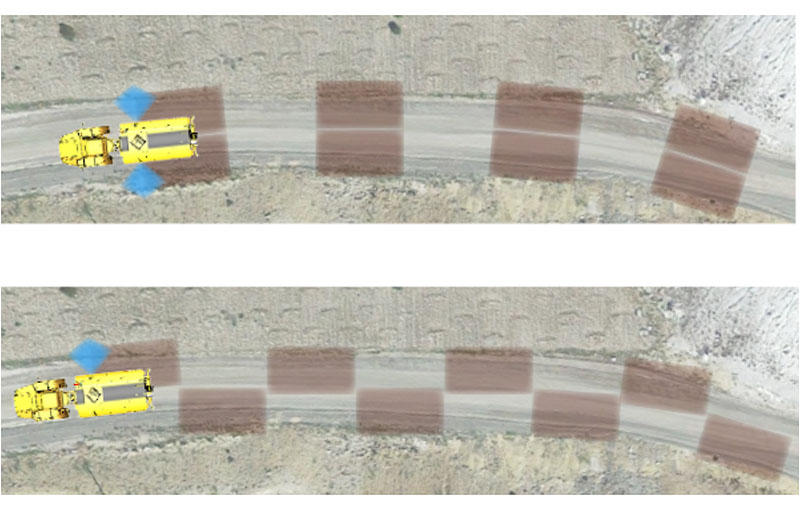

Our team analyzes complex data, identifies trends, and finds innovative solutions to create opportunities to give our customers the most cutting-edge product solutions. Effective problem-solving allows us to offer the most efficient solutions while remaining steadfast to a high focus on maintenance and safety.

We have a high level of proficiency in computer-aided design (CAD) and simulation tools and control systems to allow for the most innovative and optimized designs that focus on efficiency, cost-effectiveness, and sustainability.

Effective Communication and Leadership

We strive every day for strong communication skills that foster collaboration within our team and other departments. Our goal is to work together to achieve results-based solutions for our customers from the original equipment build to after-sale parts and product support.

We collaborate on the factory floor with our fabrication and assembly teams through every step of the build to ensure our final product is of the highest quality fit and finish.

Safety Consciousness and Compliance

Our engineering team prioritizes safety by adhering to regulations and compliance within industry regulations. Focusing on best practices ensures the well-being of our customers and the longevity of our equipment. Prioritizing safety is non-negotiable.

Rigorous risk assessments, hazard identification, and safety protocols are integral to every stage of the engineering process. Our quality control procedures, including inspections, testing, and validation, guarantee reliable and durable outcomes for our customers.

GROUND FORCE FLUID LEVEL MONITORING (FLM)

Explore Cutting-Edge Engineering in 3D

Explore our collection of immersive 3D videos showcasing the latest in engineering innovation and technology. Our forward-thinking, innovative engineering team in manufacturing is dedicated to pushing the boundaries of technology and efficiency.